-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

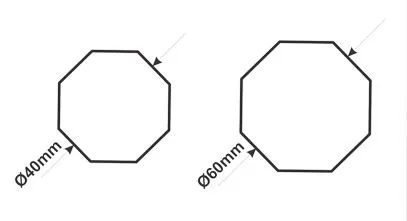

High-Precision Octagonal Tubes for Rolling Shutter Systems

Jan 17, 2026

What Is a Rolling Shutter Octagonal Tube?

An octagonal tube is a hollow metal tube with eight flat sides, offering a unique combination of strength, stability, and aesthetic appeal. Compared with round or square tubes, the octagonal shape provides enhanced torsional resistance and better load distribution, making it suitable for both structural and decorative applications. Octagonal tubes are commonly manufactured in steel, stainless steel, aluminum, or other alloy materials according to specific project requirements.

The octagonal shape allows the shutter curtain to attach securely and rotate smoothly, making it ideal for both manual and motorized rolling shutters.

Why Use an Octagonal Tube?

Compared with round tubes, octagonal tubes offer:

-

Better grip for shutter curtains

-

Higher torsional strength

-

More stable rotation

-

Improved compatibility with tubular motors and accessories

Custom Manufacturing

Rolling shutter octagonal tubes are typically custom-made, with specifications tailored to the shutter system, including:

-

Outer diameter (e.g. 40mm, 60mm, 70mm, etc.)

-

Wall thickness

-

Tube length

-

Material and surface treatment

Roller shutter accessories galvanized octagonal tube for 40mm,60mm,70mm.

| Type: | oct40 | oct60 | oct70 |

| Thickness: | 0.6mm | 0.6mm/0.8mm | 1.0mm/1.2mm |

| Material: | Galvanized | ||

| Length: | 5.8M/PC,and we can produce as per request | ||

Manufacturing Process of Octagonal Tubes

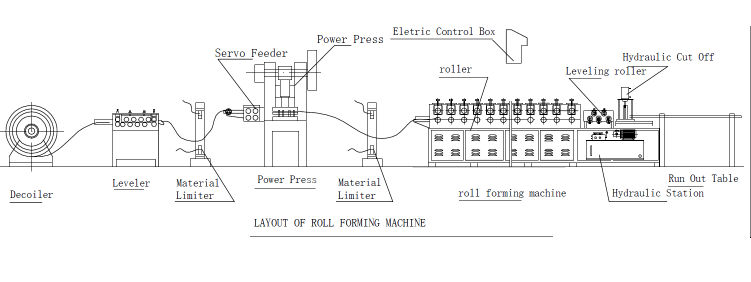

PRODUCTION FLOW

- Steel Coil –> Servo feeder–>Punching Machine –> Roll Forming Machine –> Cut Off –> Stacker –> Packaging Octagonal Tube

Since octagonal tubes are typically custom-made products, they are produced according to customer drawings, dimensions, and technical specifications. The manufacturing process generally includes the following steps:

-

Material Selection

High-quality raw materials such as carbon steel, stainless steel, or aluminum are selected based on mechanical performance, corrosion resistance, and application environment. -

Cutting and Forming

Flat metal sheets or strips are precisely cut and then formed into an octagonal shape using roll forming or press bending machines. Each angle and side length is carefully controlled to ensure dimensional accuracy. -

Straightening and Sizing

-

Surface Treatment (Optional)

Depending on the application, surface treatments such as galvanizing, powder coating, anodizing, or polishing can be applied to enhance corrosion resistance and appearance. -

Quality Inspection

Final inspections include dimensional checks, and mechanical testing if required. Only qualified products proceed to packaging and delivery.

This line is fully automatically and high speed 30m/min, with auto stacker and packaging to save labors.

Applications of Octagonal Tubes

Octagonal tubes are widely used in various industries, including:

-

Lighting Poles and Street Lamps

Octagonal tubes are commonly used as lamp posts due to their high strength, wind resistance, and clean appearance. -

Construction and Structural Engineering

Used in building frames, support columns, railings, and architectural structures where stability and aesthetics are both important. -

Transportation Infrastructure

Applied in traffic sign poles, signal poles, and guardrail systems. -

Furniture and Decorative Structures

Suitable for modern furniture frames, display stands, and decorative metal structures. -

Industrial Equipment

Used in machinery frames, equipment supports, and customized industrial components requiring enhanced rigidity.

Conclusion

Octagonal tubes are versatile, high-performance metal components that combine strength, stability, and design flexibility. As a fully customized product, they can be manufactured to meet specific engineering and application requirements. With precise manufacturing processes and strict quality control, octagonal tubes provide reliable solutions for construction, infrastructure, and industrial projects.

Related News

October 26, 2016

The Most Successful Engineering Contractor