-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

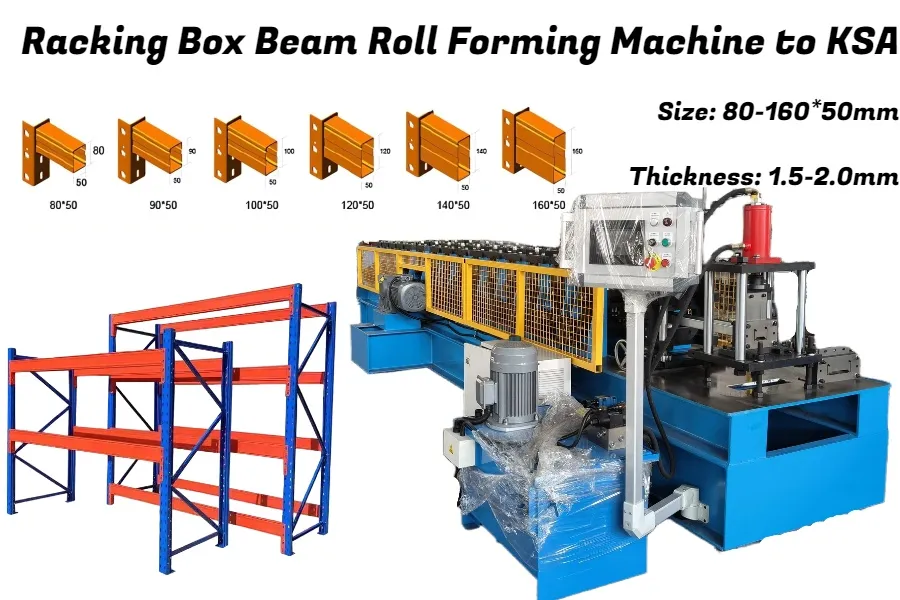

Automatic Box Beam Roll Forming Machine Successfully Shipped to Saudi Arabia

Jan 14, 2026

We are pleased to announce the successful shipment of our automatic Box Beam Roll Forming Machine to Saudi Arabia, marking another important milestone in our ongoing cooperation with Middle Eastern markets. This project reflects our strong manufacturing capability, advanced roll forming technology, and deep understanding of the warehouse racking industry.

The delivered machine is designed to produce box beams with adjustable widths from 80 mm to 160 mm, using steel thicknesses ranging from 1.5 mm to 2.0 mm. Thanks to its automatic width-adjustable system, the machine allows operators to easily change product sizes through parameter settings, without the need for manual roller replacement or mechanical adjustment. This feature significantly reduces setup time and improves production efficiency, making it ideal for customers who require flexible manufacturing solutions.

Advanced Width Adjustment Technology

One of the key highlights of this box beam roll forming machine is its automatic width adjustment function. By entering the required beam width on the control system, the machine automatically adjusts the forming stations to produce the desired size. This intelligent design enables manufacturers to respond quickly to different project requirements and market demands.

Compared with traditional roll forming machines that require time-consuming manual adjustments, this system offers:

-

Faster size changeover

-

Higher dimensional accuracy

-

Reduced labor intensity

-

Improved overall production efficiency

This technology is especially valuable for customers producing warehouse racking systems with multiple beam specifications.

Box Beam Forming Process

The box beam produced by this machine is formed through a two-step process. First, the roll forming line produces two identical C-shaped profiles. These C profiles are then aligned and fed into a joint machine, where they are mechanically joined together to form a strong and stable box beam structure.

This forming method ensures excellent load-bearing performance and structural rigidity, which are essential for warehouse racking applications. The jointing process is stable and precise, guaranteeing consistent beam quality throughout mass production.

Main Application: Warehouse Racking Systems

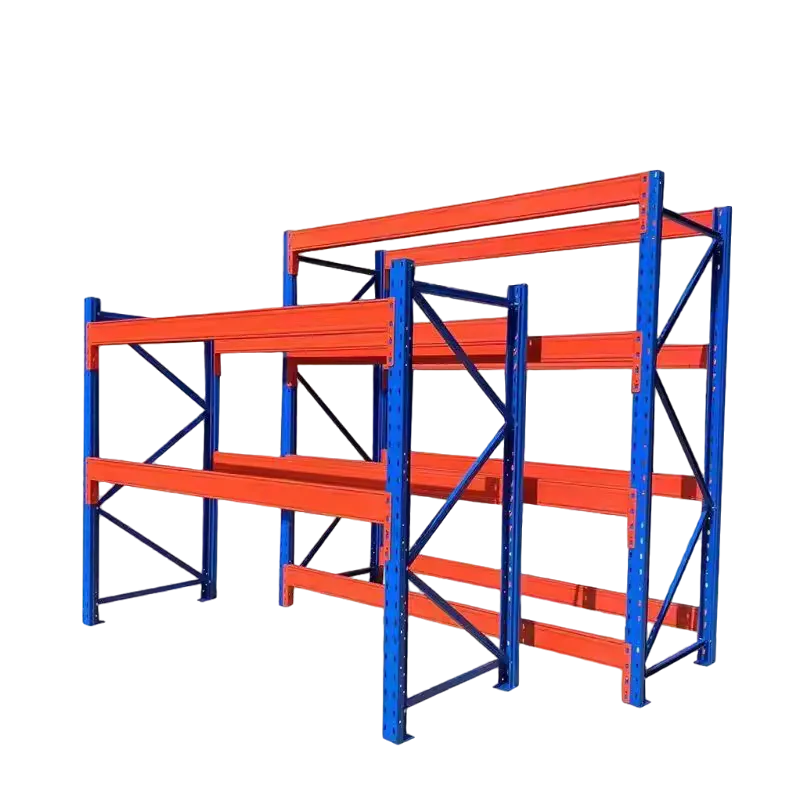

The finished box beams are primarily used in warehouse storage racks, including pallet racking systems commonly found in logistics centers, distribution warehouses, and industrial storage facilities. Due to their closed-section design, box beams offer superior strength compared to open profiles, making them suitable for heavy-duty storage applications.

With the rapid development of logistics and warehousing infrastructure in Saudi Arabia and the broader Middle East region, demand for reliable and high-capacity racking systems continues to grow. This machine is well-positioned to support such projects by providing efficient, high-quality beam production.

Successful Delivery and Customer Confidence

Before shipment, the machine underwent comprehensive testing and inspection to ensure stable performance, accurate forming, and smooth operation. After final approval, it was carefully packed and loaded for overseas delivery to Saudi Arabia.

This successful shipment demonstrates not only the reliability of our box beam roll forming solution, but also the trust placed in us by our Saudi customer. We remain committed to providing professional technical support, installation guidance, and long-term after-sales service to ensure smooth production after commissioning.

Looking Ahead

As global demand for automated roll forming equipment continues to rise, we will keep investing in technology innovation and product optimization. This box beam roll forming machine shipment further strengthens our presence in the Middle East market and reinforces our reputation as a reliable supplier of roll forming solutions for warehouse racking systems.

Related News

October 26, 2016

The Most Successful Engineering Contractor