-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

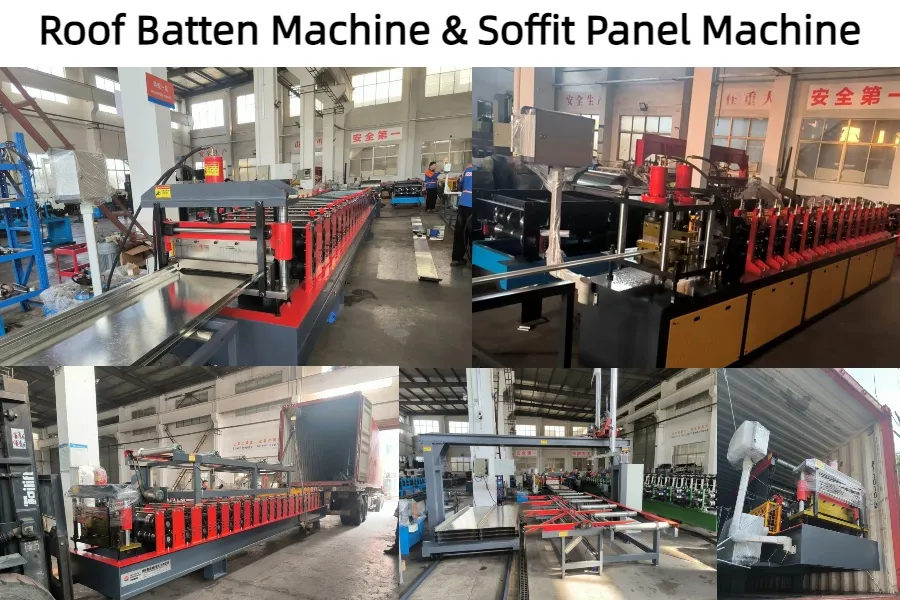

Two Roll Forming Machines Loaded for Australia as Long-Term Partnership Continues to Grow

Dec 17, 2025

On December 17, our factory site was filled with focused activity as workers carefully prepared two advanced roll forming machines for container loading. The machines, a roof batten roll forming machine and a soffit panel roll forming machine equipped with an automatic stacker, are scheduled to be shipped to Australia. This shipment represents not only another successful delivery but also the continuation of a strong and growing partnership with one of our long-term Australian customers.

Australia has long been one of our most important overseas markets. Over the years, we have supplied a wide range of roll forming machines to customers across the country, supporting industries such as light steel framing, roofing systems, and exterior cladding solutions. The Australian construction market places high demands on product consistency, durability, and automation, and our machines are designed specifically to meet these expectations. This latest shipment further strengthens our presence in the region and reflects the confidence Australian customers have in our equipment and service.

The customer receiving these machines has already purchased a total of six roll forming machines from us. While two machines are being shipped this time, several others are still in production and will be delivered in future shipments according to the agreed schedule. Such repeat and multi-machine orders are a clear indication of customer satisfaction and long-term trust, especially in a competitive market where reliability and after-sales support are critical.

One of the machines in this shipment is a roof batten roll forming machine, which is particularly noteworthy because it is the second machine of the exact same model purchased by this customer. After operating the first machine successfully in their production line, the customer decided to invest in an identical unit to expand capacity and increase output efficiency. Roof battens are essential components in modern roofing systems, especially in metal roofing applications, where dimensional accuracy and consistent profile quality are crucial for proper installation and long-term performance.

Our roof batten roll forming machine is designed to deliver stable production, uniform profile dimensions, and smooth surface quality. It supports continuous operation and is suitable for mass production, helping manufacturers meet increasing market demand while maintaining high standards. By choosing to purchase the same machine again, the customer can seamlessly integrate the new unit into their existing production workflow, reducing training time and minimizing operational risk.

The second machine in this shipment is a soffit panel roll forming machine with an automatic stacker, a solution developed to improve efficiency and protect finished products. Soffit panels are widely used in residential, commercial, and industrial buildings to cover roof eaves, improve ventilation, and enhance the overall appearance of structures. As demand for metal soffit panels continues to grow, manufacturers are increasingly looking for automated solutions to reduce labor costs and improve handling quality.

To meet this need, we equipped the soffit panel roll forming machine with a fully automatic stacking system. This system is capable of automatically flipping the panels and stacking them neatly after forming. During the design process, special attention was given to product protection. Rubber padding was added to the automatic flipping device to prevent scratches or surface damage during handling. This is especially important for soffit panels, which often have visible surfaces and may be pre-painted or coated.

The automatic stacker not only improves efficiency but also ensures consistent stacking, making packaging, storage, and transportation easier and safer. By reducing manual handling, the system helps manufacturers lower labor intensity while maintaining high product quality.

As the machines were loaded into containers on December 17, our team conducted final inspections to ensure all components were properly secured and protected for long-distance sea transportation to Australia. Every shipment reflects our commitment to quality, from machine manufacturing to packaging and logistics.

This delivery marks another milestone in our cooperation with Australian customers. With more machines still to be shipped under this order, we look forward to continuing our collaboration and supporting our customers’ growth with reliable roll forming solutions, customized configurations, and responsive technical support.

Related News

October 26, 2016

The Most Successful Engineering Contractor