-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Customized Roll Forming Solutions Delivered to Australia: Efficiency, Space Saving, and Smart Design in Action

Jan 30, 2026

On January 26, our factory marked another important step in international cooperation as two customized roll forming machines were loaded into containers and prepared for shipment to Shanghai Port. These machines were ordered by a customer from Australia and represent the final delivery of a comprehensive six-machine order. This project showcases not only advanced manufacturing capability, but also a strong focus on customer value, efficiency, and practical engineering innovation.

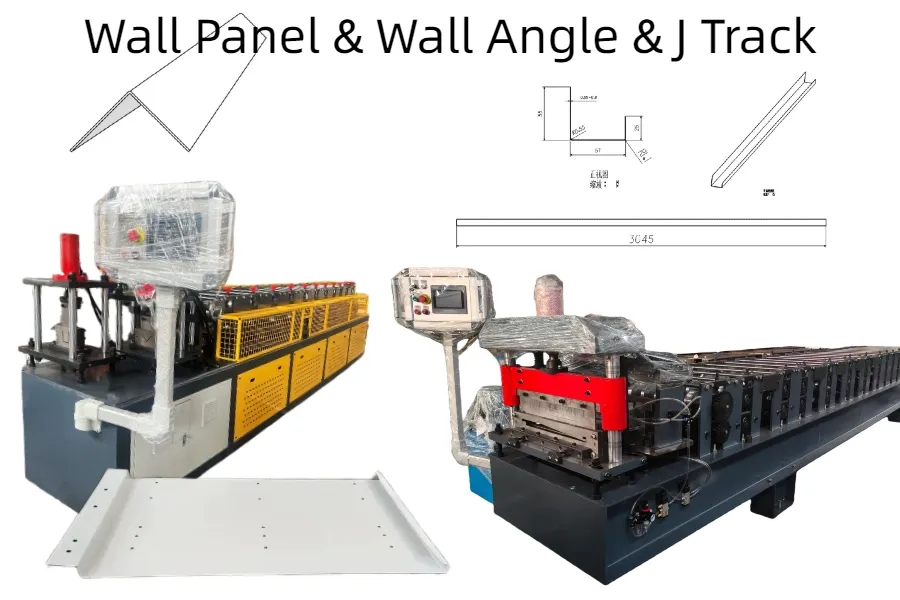

The Australian customer placed a one-time order for six roll forming machines to support the development of their local steel profile manufacturing business. From the early technical discussions to final production and shipment, this project was handled as a complete solution rather than a standard equipment sale. The two machines shipped on January 26 are a Wall Panel Roll Forming Machine with a punching function and a 2 in 1 U Channel and Wall Angle Roll Forming Machine, both customized to meet the customer’s operational needs.

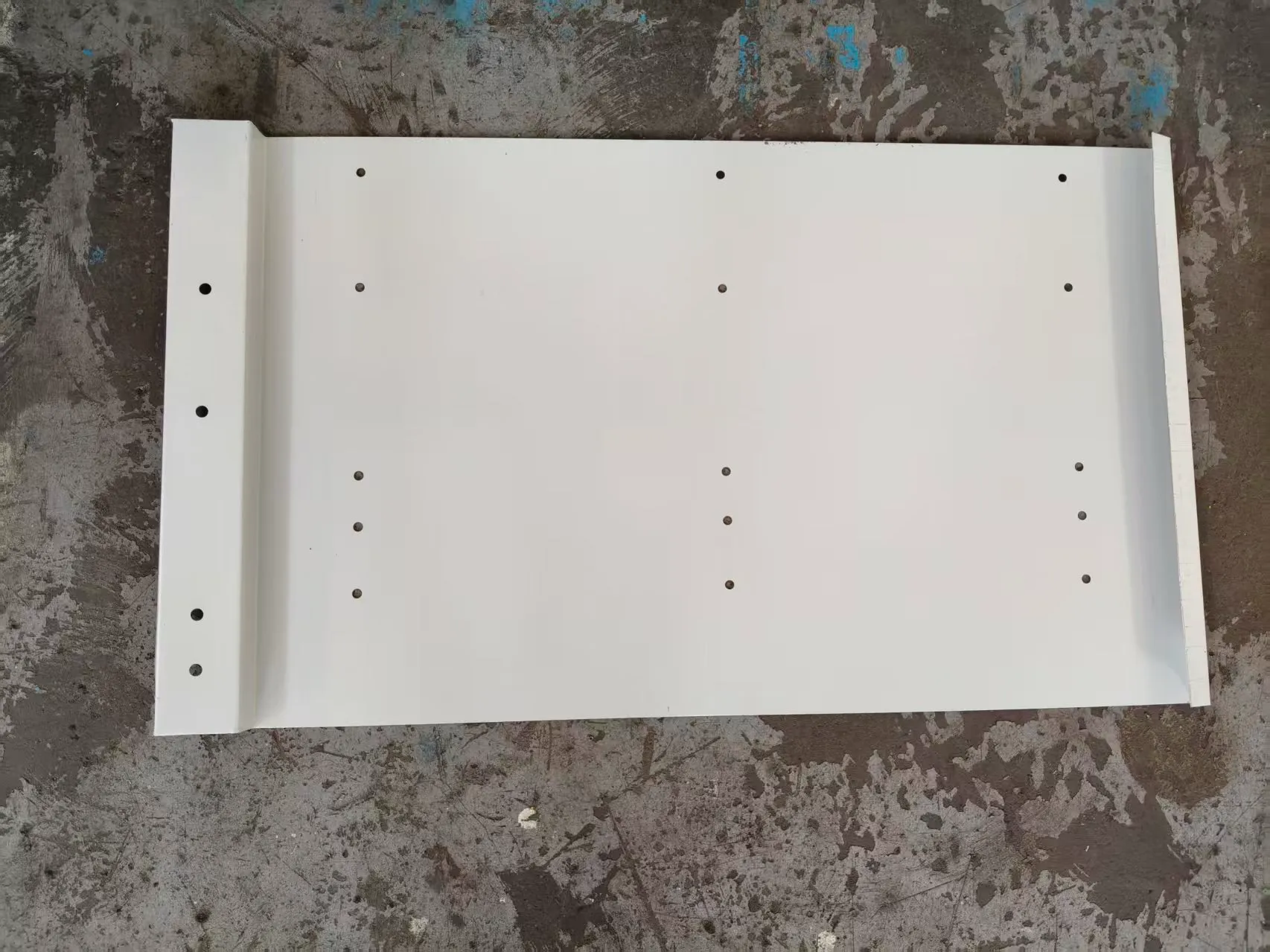

For the Wall Panel Roll Forming Machine, the customer required the ability to produce panels with precise holes for installation and assembly. To meet this requirement, our engineering team integrated a dedicated punching device directly into the roll forming line. This design allows holes to be punched automatically as the panel is being formed, ensuring accurate positioning and consistent quality.

By adopting this integrated solution, the customer can avoid manual punching or secondary processing after forming. This not only improves production efficiency, but also reduces the risk of errors caused by repositioning materials. The result is a smoother workflow, lower labor input, and improved productivity—key advantages for manufacturers operating in competitive construction markets such as Australia.

The second machine shipped is a 2 in 1 U Channel and Wall Angle Roll Forming Machine, which reflects a growing demand for flexible and space-saving production equipment. Instead of installing two separate machines, the customer chose a combined solution that allows both U channel and wall angle profiles to be produced on a single machine. Our design places the two forming systems side by side, sharing the same machine base, electrical control system, and safety structure.

This innovative layout brings multiple benefits. It reduces equipment investment, saves valuable workshop space, and lowers energy consumption. It also makes daily operation easier, as operators can manage two product types within one system. For manufacturers seeking to optimize factory layout and control costs without sacrificing production capability, this type of combined machine is an ideal solution.

Throughout the manufacturing process, strict quality control was applied. Each forming station, roller set, punching unit, and cutting system was produced using high-precision machining equipment. Before shipment, both machines were fully assembled and tested in our factory to ensure stable operation, accurate forming, and reliable punching performance. Only after passing internal inspection were the machines approved for packing and container loading.

The loading process on January 26 was carefully organized by our logistics and technical teams. Proper fixing, protection, and container reinforcement were applied to ensure that the machines would arrive in Australia in perfect condition after sea transportation from Shanghai Port.

This successful delivery reflects our company’s long-term commitment to providing customized roll forming solutions rather than standard machines. By understanding customer production goals and site limitations, we are able to offer equipment that improves efficiency, saves space, and delivers strong return on investment.

We sincerely appreciate the trust of our Australian customer and are proud to support their business growth with reliable and innovative roll forming equipment. As global demand for efficient steel profile production continues to grow, we remain committed to engineering excellence, customer-oriented design, and long-term international partnerships.

If you have any interest in our machines, please feel free to contact us!

Related News

October 26, 2016

The Most Successful Engineering Contractor