-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

The Role and Application of M Purlins in Structural Framing

Dec 22, 2025

What is an M Purlin?

An M purlin is a cold-formed steel section shaped like the letter “M” in cross-section. It is commonly used in metal building systems, especially for roofing and wall framing. The design features a broad top flange, vertical web, and a narrower bottom flange, creating an efficient shape for spanning between primary structural supports (such as rafters or trusses).

Key Features & Benefits

-

Lightweight yet strong – Made from high-strength steel, M purlins provide good load-bearing capacity while keeping the structure light.

-

Easy installation – The shape allows simple connection to main frames and easy attachment of roofing/wall cladding.

-

Cost-effective – Efficient material use reduces overall steel consumption and lowers construction costs.

-

Versatility – Suitable for various building types, from industrial warehouses and workshops to agricultural and commercial buildings.

Typical Applications

-

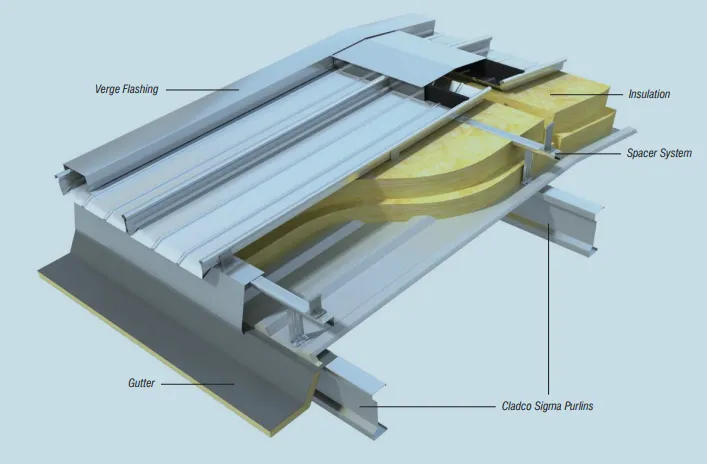

Roof systems – As secondary structural members to support roof sheets or panels.

-

Wall girts – Horizontal members for attaching wall cladding.

-

Mezzanine floors and loft structures – As joists or supports for decking.

-

Canopies and carports – Light framing for overhead covers.

Why Choose Sigma M Purlins?

M purlins offer a practical balance of strength, economy, and adaptability. They work well in both simple and complex building designs and are compatible with various insulation and cladding options. For anyone planning a steel-framed building, M purlins are a reliable and widely used solution.

Where to use the Sigma M purlin:

Roof purlins:

Use sleeves to shorter purlin or assemble 2-span purlin staggered

Keep a space of approx. 15 mm between the truss and the purlin

Eaves beams are supplied with an angled top flange, so only 1 profile is needed where roof and wall meet

How to make sigma M purlin:

Working process:

Flat Steel Coil -> feeding & leveling -> Punching to make connection holes ->Roll forming -> Hydraulic cutting -> Final "M" Shape

1. Raw Material: Coiled Steel

The process starts with large coils of galvanized steel. The steel is often Galvalume (an aluminum-zinc alloy coating) or pre-galvanized to provide inherent corrosion resistance. The base steel is high-strength, typically with a yield strength of 550 MPa (Grade 550)

2. Hydraulic punching

-

As the steel is being formed, holes are pre-punched at precise intervals. These include:

-

Slotted holes on the top flange for easy adjustment during roofing installation.

-

Bolt holes on the web for connecting to the main building frame (rafts or columns).

-

Splice holes for joining purlin lengths end-to-end.

-

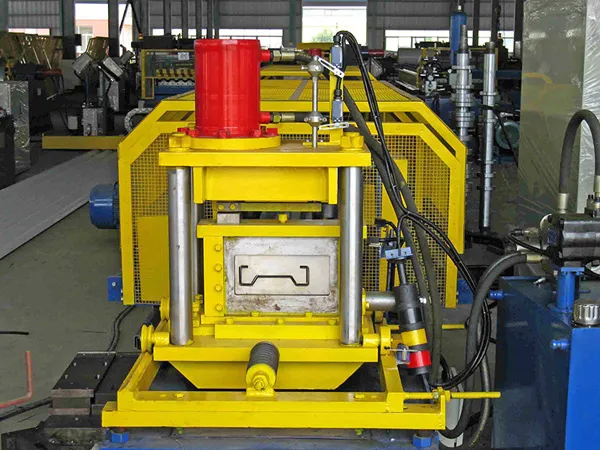

3. Sigma M purlin Roll Forming

This is the heart of manufacturing. The steel coil is fed into a roll forming machine.

The machine consists of a series of paired roller dies, arranged in stations.

As the flat steel strip passes through each station, the rollers gradually and precisely bend it into the final "M" shape.

4.Hydraulic punching

After forming and punching, the continuous purlin is cut to the specified custom length using a cut-off device, burr-free cut.

In summary, M purlins are made through a highly automated, precise, and efficient cold roll-forming process that transforms coiled, coated steel strips into the familiar, strong, and lightweight structural sections used worldwide.

Related News

October 26, 2016

The Most Successful Engineering Contractor