-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Mexico RN100-35 Roof Metal Sheet Deck Roll Forming Machine

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Description

Specification

Main Features:

The RN-100/35 (RN 100) sheet is a Ribbed profile on a stationary rolling machine using the best quality steel rolls. Its geometric configuration is ideal since it has a double anti-siphon channel which provides excellent drainage capabilities. Due to its high structural resistance, it can be specified on industrial warehouse roofs where structural capacity is required, in addition to designing with low slopes (minimum slope of 6%).

In addition to being widely used on roofs, it is also recommended for use on facades due to its versatility and lightness in

installation.

Advantages RN-100/35

It has an excellent drainage capacity due to its 3.50 cm camber and its exclusive design that involves the double anti-siphon channel.

Great structural resistance, ideal for the construction of high-specification industrial buildings.

It has an excellent drainage capacity due to its 3.50 cm camber and its exclusive design that involves the double anti-siphon channel.

Great structural resistance, ideal for the construction of high-specification industrial buildings.

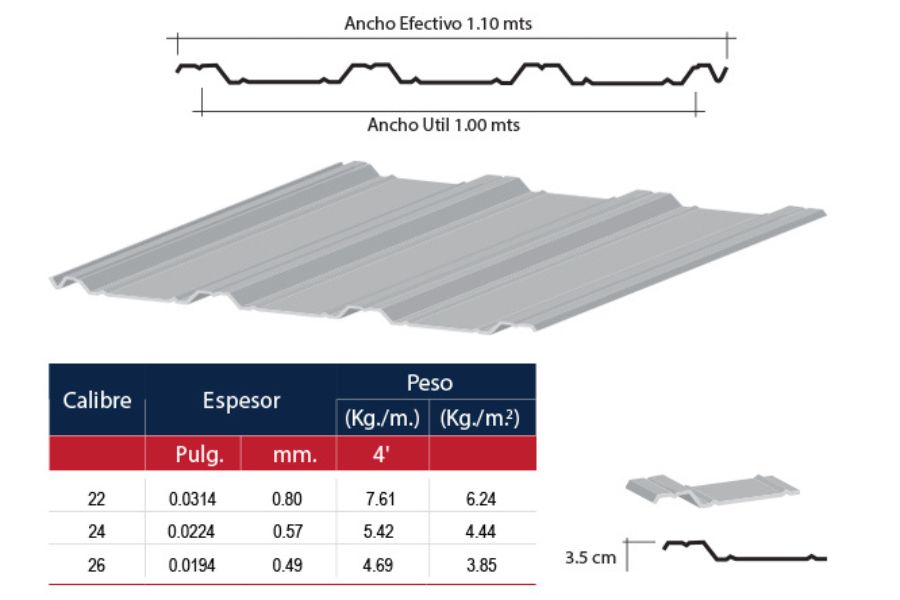

RN-100/35 Sheet Characteristics

Excellent structural capacity and drainage

It has a double anti-siphon channel.

Excellent structural capacity and drainage

It has a double anti-siphon channel.

1.Technical parameter

| Suitable Raw Material | |

|---|---|

| Material | PPGI and PPGL Coils |

| Thickness | 0.3-0.7mm |

| Coil width | 1220mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 22 |

| Diameter of forming rollers shafts | 75mm |

| Roll Forming Speed | 15-20m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 11kw |

| Hydraulic unit motor power: 3kw | |

| Electric voltage | According to customer’s requirement |

2.Machine List

|

5 tons passive de-coiler

|

1 set

|

|

Main roll forming machine

|

1 set

|

|

PLC Control box

|

1 unit

|

|

Hydraulic station

|

1 unit

|

|

Safety cover

|

1 set

|

|

Spare parts

|

1 set

|

3.Technical process

Decoiler → Feeding →roll forming →cutting →Output tables

4. Profile Drawing

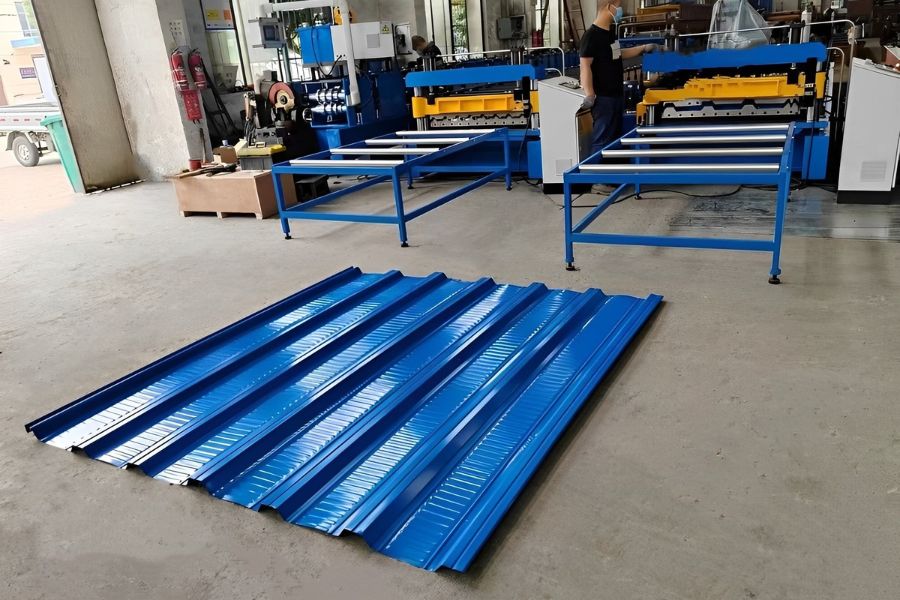

5. Finished Products

6, Application

Optional configuration

Optional Configuration For Your Choice

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)