In the world of modern construction, efficiency and precision are paramount. One key innovation that has transformed the industry is the deck floor roll forming machine. This sophisticated piece of equipment plays a crucial role in producing high-quality deck flooring materials that meet the demands of contemporary building projects. In this blog, we'll explore what deck floor roll forming machines are, how they work, their advantages, and their applications in construction.

What is a Deck Floor Roll Forming Machine?

A deck floor roll forming machine is a specialized equipment used to produce metal decking sheets, which are essential components in many commercial and industrial buildings. These machines take raw metal coils and transform them into finished products through a series of rolling and shaping processes. The result is a strong, durable, and lightweight decking solution ideal for various construction applications.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Key Components of a Roll Forming Machine

- Feeding Mechanism: This section ensures that the raw material is fed into the machine consistently and accurately.

- Roll Forming Stations: Multiple stations progressively shape the metal into the desired profile.

- Cutting Mechanism: Once the desired length is achieved, the cutting mechanism precisely trims the finished product.

- Control System: Modern machines are equipped with advanced control systems that allow for precise adjustments and monitoring.

How Does It Work?

The operation of a deck floor roll forming machine involves several steps:

- Material Feeding: The metal coil is fed into the machine.

- Roll Forming: As the coil passes through the roll stations, it is gradually shaped into the desired deck profile.

- Cutting: Once the metal reaches the desired length, it is cut using an automated cutting mechanism.

- Collection: The finished deck sheets are collected and prepared for shipment or further processing.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Decoiler Roll Forming Machine

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Cutting Auto Stacker

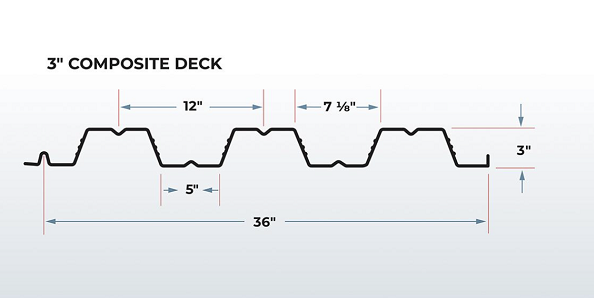

Some Common Profile Drawings

Advantages of Deck Floor Roll Forming Machines

- Efficiency: These machines can produce large quantities of decking sheets in a short amount of time, significantly speeding up the construction process.

- Precision: With advanced control systems, roll forming machines ensure that every sheet is manufactured to exact specifications, reducing waste and rework.

- Cost-Effectiveness: While the initial investment may be high, the long-term savings in labor and material costs can be substantial.

- Versatility: Roll forming machines can be customized to produce various profiles and thicknesses, making them suitable for different types of projects.

Applications in Construction

Deck floor roll forming machines are used in a variety of construction applications, including:

- Commercial Buildings: Many modern commercial structures use metal decking for floors and roofs due to their strength and lightweight properties.

- Industrial Facilities: Warehouses and factories benefit from the durability and ease of installation of metal decking.

- Residential Projects: Increasingly, metal decking is being used in high-end residential builds for its aesthetic and structural benefits.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Choosing the Right Roll Forming Machine

When selecting a deck floor roll forming machine, consider the following factors:

- Production Capacity: Ensure the machine can meet your project’s demands.

- Profile Customization: Look for machines that allow for a variety of deck profiles.

- Automation Level: Higher automation can lead to greater efficiency and reduced labor costs.

- Support and Maintenance: Choose a manufacturer that offers excellent support and maintenance services.

Conclusion

Deck floor roll forming machines are indispensable in the construction industry, providing a blend of efficiency, precision, and cost-effectiveness. As the demand for high-quality decking solutions continues to grow, investing in a reliable roll forming machine can significantly enhance your production capabilities. Whether you’re involved in commercial, industrial, or residential construction, these machines are poised to play a pivotal role in the future of building design and construction.