-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

The Backbone of Modern Warehousing: A Deep Dive into Racking Vertical Box Beams

Nov 05, 2025

The Backbone of Modern Warehousing: A Deep Dive into Racking Vertical Box Beams

Introduction: The Unsung Hero of Supply Chain Efficiency

In the vast, interconnected world of global logistics and e-commerce, warehouse efficiency is paramount. At the very core of this efficiency lies a deceptively simple yet brilliantly engineered component: the racking vertical box beam. These are the upright frames that form the skeleton of every pallet racking system, silently bearing immense loads and enabling the high-density storage that powers our modern economy. This blog explores the critical role of these beams, their design specifications, and the sophisticated manufacturing process that ensures they can handle the tremendous weight and stress of daily warehouse operations.

.webp)

What is a Racking Vertical Box Beam?

A racking vertical box beam, often called an upright frame or column, is the vertical structural member in a pallet racking system. It is not a solid beam but a hollow, rectangular or square tubular section, typically manufactured from high-strength steel. These uprights are characterized by a series of precisely punched holes or slots along their height, which allow for the adjustable insertion of the horizontal load beams that support the pallets.

The box beam’s design is a masterpiece of structural engineering, offering an exceptional strength-to-weight ratio. The hollow shape provides maximum resistance to bending and buckling under heavy compressive loads, while the punched holes are strategically placed and shaped to minimize stress concentration.

The Critical Role in Storage Systems

The vertical box beam is the primary load-bearing element in a racking system. Its responsibilities are immense:

-

Supporting Vertical Loads: Each upright must support the cumulative weight of all the pallets stored on its side of the bay, from the top level to the bottom. This can amount to tens of thousands of kilograms.

-

Resisting Lateral Forces: The uprights must provide stability to the entire structure, resisting forces from forklift impacts, seismic activity (in certain regions), and the dynamic loads of pallets being inserted and removed.

-

Enabling Flexibility: The standardized punching pattern allows warehouse managers to easily reconfigure shelf heights to accommodate different pallet sizes, making the storage system highly adaptable.

Deconstructing the Manufacturing Process: A Two-Stage Marvel

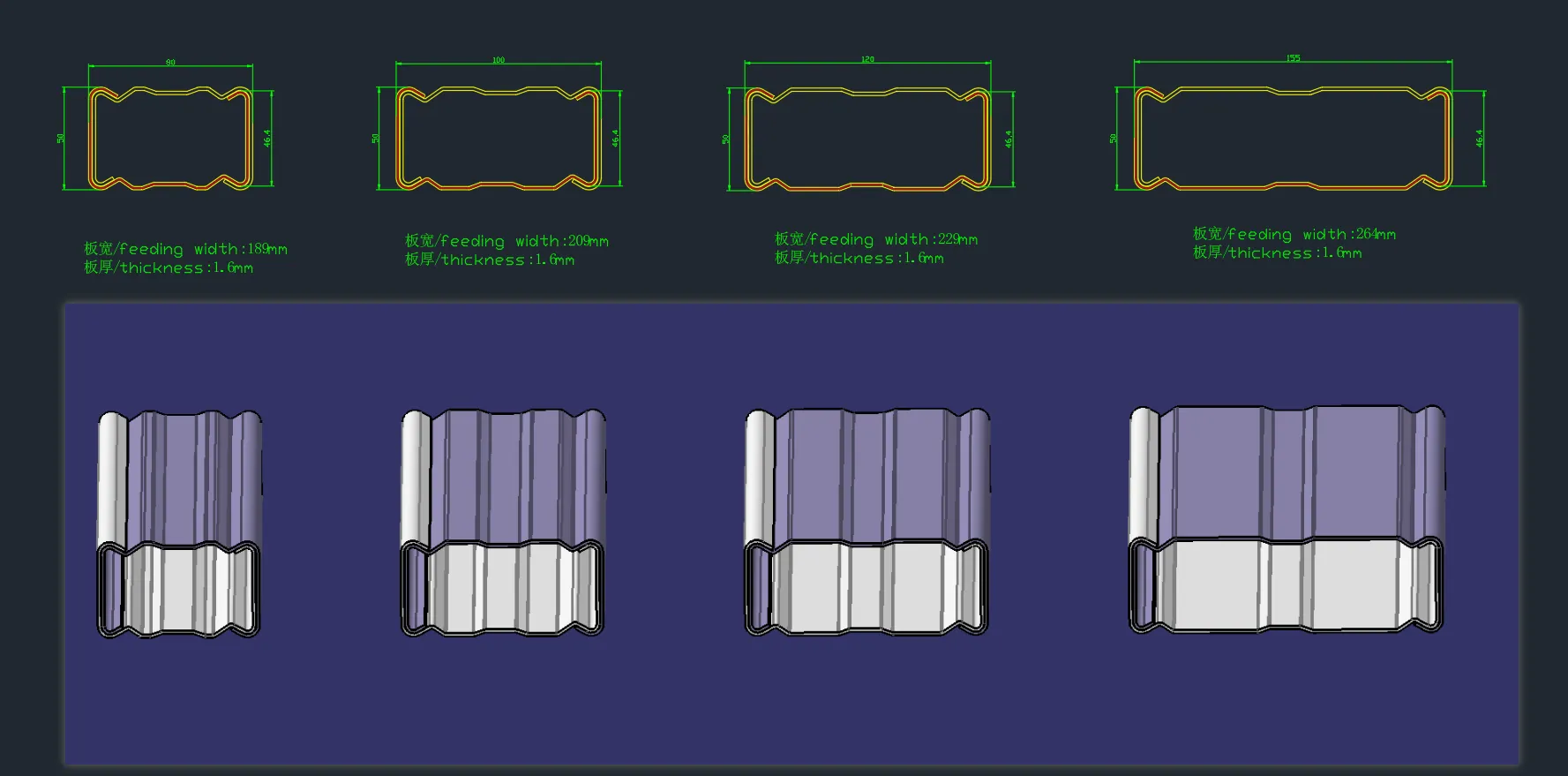

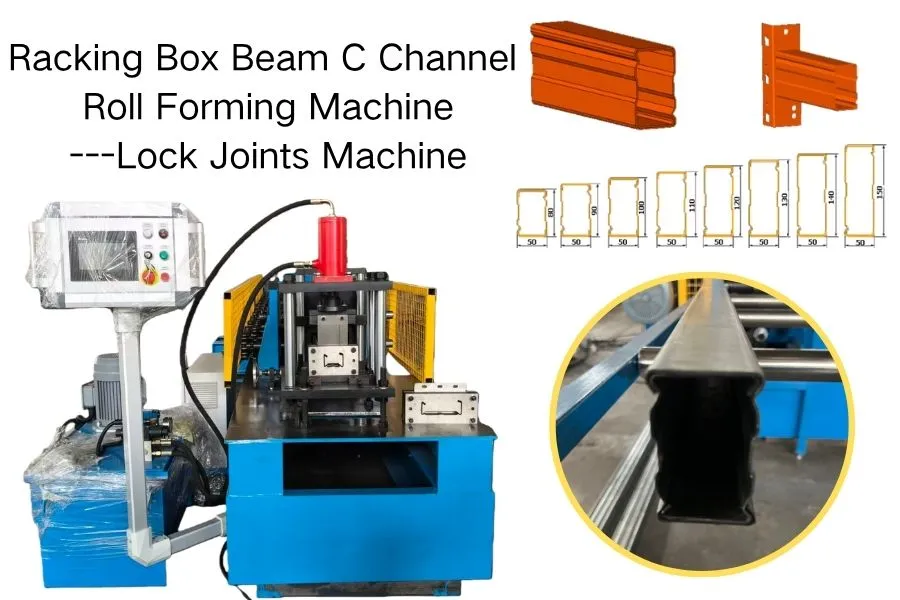

The creation of a racking upright is a precise, automated operation. The most advanced method involves a two-stage process: C-channel formation followed by lock joint seam welding.

Stage 1: The Birth of the C-Channel

The journey begins with a massive coil of high-tensile steel, typically conforming to grades like S350GD, with a yield strength of 350 MPa.

-

Coil Loading & Decoiling: The steel coil is mounted onto a decoiler, which feeds the raw material into the production line at a controlled, consistent rate.

-

Pre-Punching (The Critical Step): Before any forming occurs, the flat steel strip passes through a precision punching station. Here, a hydraulic press with custom-designed tooling punches the entire pattern of teardrop, round, or other specialized holes into the flat metal. Performing this operation on a flat sheet is far more accurate, efficient, and cost-effective than trying to punch a fully formed box section.

-

Roll Forming the C-Channel: The punched flat strip then enters the roll forming machine. This machine consists of a series of tandem stations, each with a set of hardened steel rollers. Each station makes a small, incremental bend. Over the course of 12 to 20 stations, the flat strip is gradually and precisely shaped into a uniform C-channel profile. This C-channel already has the basic shape and all the necessary holes of the final upright.

Stage 2: The Transformation via Lock Joint Seam Welding

The C-channel is robust, but to achieve the ultimate strength and torsional rigidity of a box section, it must be closed.

-

Edge Preparation: The open edges of the C-channel are precisely formed into a specific interlocking profile, often a hook-and-lap design.

-

Closing and Welding: The C-channel is guided into the lock joint seam welder. Here, the prepared edges are brought together under pressure. A high-frequency electrical current is passed through the seam, instantly heating the metal edges to a molten state. The pressure forges them together, creating a continuous, homogenous weld along the entire length of the beam.

-

The Result: What emerges is a perfect, seamless box beam. This process creates a weld that is often as strong as, or even stronger than, the parent material itself.

Why This Manufacturing Method is Superior

-

Unmatched Strength: The continuous, seamless weld creates a uniform structure with superior load-bearing capacity and resistance to torsional twisting compared to other methods.

-

Excellent Surface Finish: The process results in a clean, smooth seam with no spatter, requiring minimal post-production finishing.

-

High Efficiency: It is a continuous, high-speed production process ideal for manufacturing long lengths of uprights with consistent quality.

-

Material Integrity: The cold-forming and HF welding process minimizes heat distortion, preserving the structural properties of the steel.

Conclusion

The racking vertical box beam is a pinnacle of industrial design, a component whose reliability we take for granted. The sophisticated, two-stage manufacturing process of roll-forming a pre-punched C-channel and transforming it via lock joint welding is what gives this humble component the Herculean strength required to uphold the global supply chain. In our next blog, we will delve deeper into the engineering specifications, quality control, and the pivotal role of the lock joint machine in ensuring every beam is built to last.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria