-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

The Applications of DIN Rail Roll Forming Machines: Empowering Industries with Precision and Efficiency

Dec 02, 2024

The Applications of DIN Rail Roll Forming Machines: Empowering Industries with Precision and Efficiency

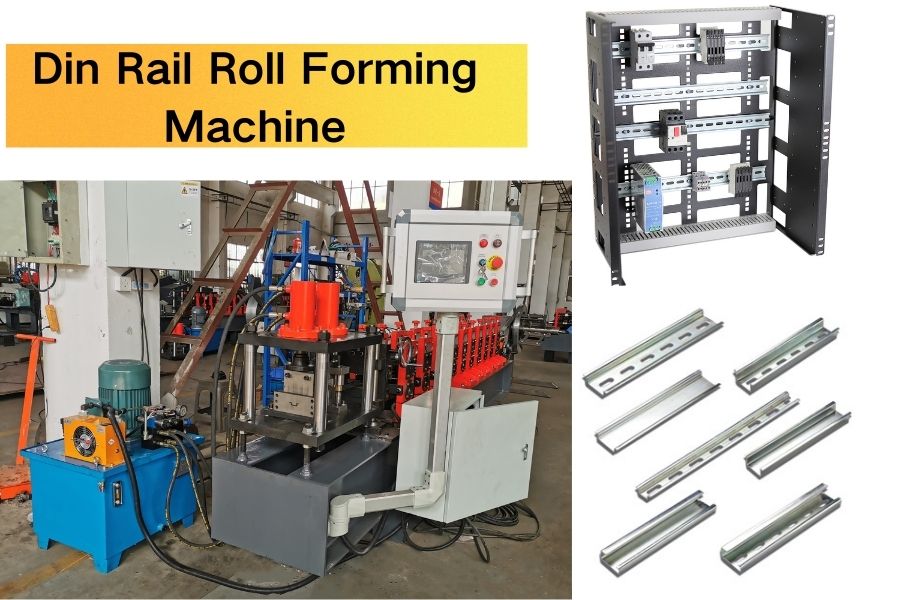

DIN rail roll forming machines have revolutionized the manufacturing landscape, offering unmatched precision, speed, and versatility in producing DIN rails. These rails are standardized metal profiles used widely in electrical and industrial applications, providing a framework for mounting circuit breakers, relays, and other components. But the impact of DIN rail roll forming machines goes beyond mere production. Their applications span across various industries, enabling manufacturers to meet the demands of modern engineering and infrastructure projects.

In this blog, we’ll explore the diverse applications of DIN rail roll forming machines and the advantages they bring to the manufacturing sector.

What Are DIN Rail Roll Forming Machines?

DIN rail roll forming machines are specialized equipment designed to manufacture DIN rails in large volumes. These machines operate by feeding metal strips through a series of rollers, gradually forming the material into the desired profile with precise dimensions. They can handle various materials like galvanized steel, aluminum, and stainless steel, ensuring durability and compatibility with a wide range of applications.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Key Applications of DIN Rail Roll Forming Machines

DIN rail roll forming machines play a crucial role in several industries by supporting the production of high-quality DIN rails. Here’s a closer look at their primary applications:

1. Electrical and Electronic Systems

The most prominent application of DIN rail roll forming machines is in the electrical and electronics sector. They manufacture DIN rails that serve as the backbone of electrical systems.

- Mounting Components in Control Panels: DIN rails provide a secure and standardized framework for mounting circuit breakers, relays, contactors, and terminal blocks in control panels.

- Efficient Wire Management: DIN rails help organize components, making wiring more accessible and reducing the risk of errors.

- Customization for Specific Needs: Roll forming machines can produce various DIN rail profiles (e.g., top hat or C-section rails) tailored to the requirements of different electrical installations.

2. Industrial Automation

In industrial automation, DIN rails are essential for organizing and securing components within automated systems. Roll forming machines ensure the production of rails with precise dimensions, crucial for:

- PLC (Programmable Logic Controller) Modules: Mounting PLC hardware and associated input/output devices.

- Sensor Systems: Providing a stable base for sensors, ensuring accurate placement and operation.

- Robotics and Machinery Integration: DIN rails help integrate electrical and electronic modules into complex robotic systems.

3. Telecommunications

Telecommunication networks require robust and standardized equipment mounting solutions. DIN rails produced by roll forming machines are ideal for:

- Networking Equipment: Supporting the installation of routers, switches, and other networking devices.

- Power Distribution Units (PDUs): Providing a stable mounting platform within server racks and enclosures.

- Signal Amplifiers and Splitters: Ensuring alignment and accessibility for signal management components.

Conclusion

DIN rail roll forming machines are indispensable in manufacturing, supporting a wide array of industries with their ability to produce high-precision DIN rails. From electrical systems and industrial automation to telecommunications and renewable energy, these machines enable manufacturers to meet the challenges of modern engineering with confidence.

As industries continue to evolve, the role of DIN rail roll forming machines will only grow, offering innovative solutions for the mounting and organization of critical components. For manufacturers, investing in these machines means staying ahead of the curve, ensuring quality, efficiency, and adaptability in a competitive market.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria