-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

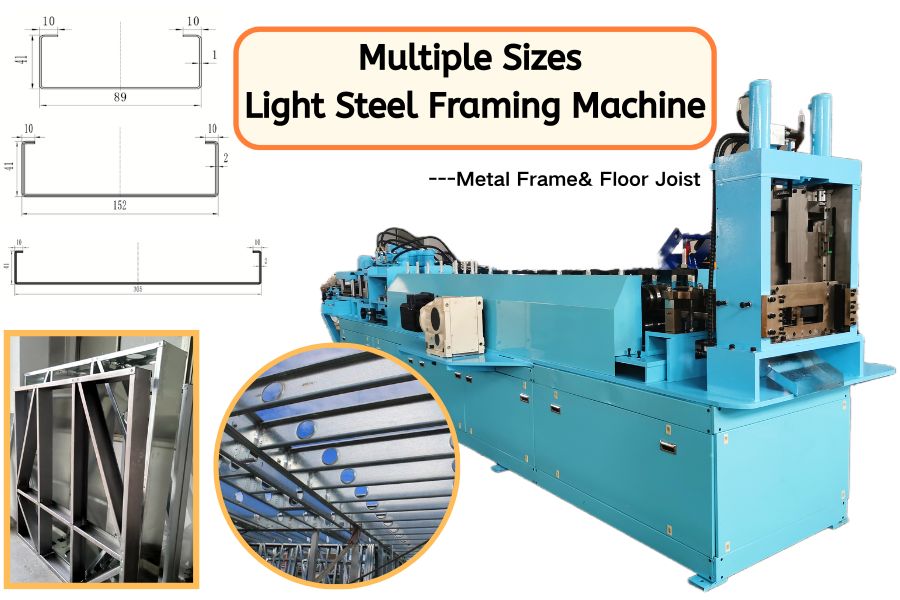

Enhancing Construction Efficiency with Multiple Sizes Light Steel Framing Machines

Mar 10, 2025

Enhancing Construction Efficiency with Multiple Sizes Light Steel Framing Machines

The construction industry is constantly seeking ways to improve efficiency, reduce costs, and enhance the quality of buildings. One of the most innovative solutions to emerge in recent years is the use of multiple sizes light steel framing machines. These machines produce metal frames and floor joists that are stronger, more durable, and more versatile than traditional wood framing. In this blog, we’ll delve into how these machines are enhancing construction efficiency and why they are becoming the preferred choice for builders worldwide.

The Need for Innovation in Construction

Traditional wood framing has been the standard in construction for decades. However, it comes with several limitations, including susceptibility to moisture, termites, and fire. Additionally, wood framing can be time-consuming and labor-intensive. Light steel framing machines address these challenges by offering a faster, stronger, and more sustainable alternative.

How Light Steel Framing Machines Work

Light steel framing machines use roll-formed steel to create metal frames and floor joists. The process involves feeding steel coils into the machine, which then shapes and cuts the steel into the desired sizes and profiles. These machines can produce frames and joists in multiple sizes, making them suitable for a wide range of construction projects.

Benefits of Multiple Sizes Light Steel Framing Machines

-

Customization: The ability to produce frames and joists in multiple sizes allows builders to customize the framing to meet the specific requirements of each project.

-

Strength and Durability: Steel frames are stronger and more durable than wood, providing better resistance to environmental factors and ensuring the longevity of the structure.

-

Speed and Efficiency: Light steel framing machines can produce frames and joists at a much faster rate than traditional methods, reducing construction timelines and labor costs.

-

Sustainability: Steel is a recyclable material, and the precision of light steel framing machines minimizes waste, making them an environmentally friendly choice.

Applications of Metal Frames and Floor Joists

Metal frames and floor joists produced by light steel framing machines are used in various construction applications, including:

-

Residential Construction: For framing walls, roofs, and floors.

-

Commercial Construction: For creating structural frameworks and partitions.

-

Industrial Construction: For constructing durable and fire-resistant structures.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Case Study: A Successful Implementation

A construction company in Australia recently adopted light steel framing machines for a large commercial project. The results were impressive:

-

Time Savings: The project was completed 25% faster than similar projects using traditional framing methods.

-

Cost Efficiency: Reduced labor costs and material waste led to significant savings.

-

Customer Satisfaction: The building owners were delighted with the durability and quality of the steel-framed structure.

Future Trends in Light Steel Framing

As technology continues to advance, we can expect to see even more innovations in light steel framing machines. Some of the trends to watch out for include:

-

Automation: Increased automation in light steel framing machines will further enhance efficiency and reduce labor costs.

-

Advanced Materials: The development of new steel alloys and coatings will improve the strength and durability of metal frames and floor joists.

-

Sustainability: Continued focus on sustainability will drive the development of more eco-friendly light steel framing machines and materials.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Conclusion

Multiple sizes light steel framing machines are revolutionizing the construction industry. Their ability to produce strong, durable, and customizable metal frames and floor joists with precision and efficiency makes them an invaluable tool for modern builders. As the demand for faster, stronger, and more sustainable construction methods continues to grow, light steel framing machines will undoubtedly play a central role in shaping the future of construction.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria