-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Comprehensive Guide to Hat Purlins: Sizes, Thickness, Applications, and the Hat Purlin Roll Forming Machine

Oct 25, 2024

Introduction to Hat Purlins

Hat purlins are essential components in the construction industry, notable for their unique shape resembling a hat. This design offers excellent strength and stability, making hat purlins ideal for diverse applications, from roofing and cladding to framing in commercial, industrial, and even residential buildings.

Hat Purlin Sizes and Thickness

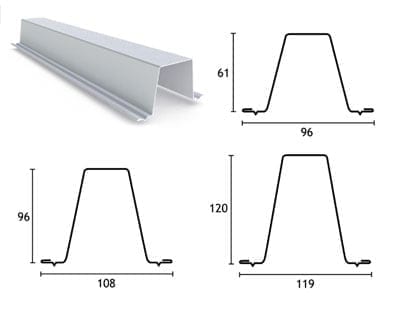

The dimensions of hat purlins vary significantly to accommodate a wide range of structural needs. Typical sizes include:

- Width: Generally 2 to 6 inches.

- Height: Ranges from 1 to 4 inches.

- Thickness: Between 0.04 to 0.12 inches (or approximately 1mm to 3mm).

These thicknesses and sizes allow hat purlins to adapt to different load-bearing requirements. For instance, thicker purlins (closer to 0.12 inches) are used in industrial structures where heavy loads need strong support, while thinner purlins (around 0.04 inches) are ideal for lighter structures such as internal frames in residential buildings.

Applications of Hat Purlins

Hat purlins have a wide range of applications, particularly due to their inherent strength and profile. Here are some of their primary uses:

-

Roofing Support: Hat purlins are a preferred choice for roofing in commercial and industrial buildings. They provide stable, reliable support for roof panels, ensuring longevity and resistance to deformation.

-

Wall Cladding Support: Hat purlins can be used as framing for exterior wall cladding systems, especially in warehouses and factory structures, as they provide durability without adding excessive weight.

-

Interior Framing: In residential applications, hat purlins are suitable for framing and partition walls, delivering a lightweight yet sturdy option for interior construction.

-

Agricultural and Storage Buildings: Hat purlins are also commonly used in the construction of storage and agricultural buildings, where structural integrity is essential without heavy, bulky framing.

The Hat Purlin Roll Forming Machine

To produce hat purlins efficiently and in high volumes, the hat purlin roll forming machine is essential. This machine automates the production process, transforming metal coils into precise, uniform hat purlins. The machine’s control system allows for customization of width, height, and thickness, enabling manufacturers to produce purlins to specific project requirements.

Key features of the hat purlin roll forming machine include:

- Adjustable Settings: Precise adjustments in size and thickness to meet client needs.

- High-Speed Production: Automated systems allow high output with minimal labor, reducing production time and costs.

- Material Efficiency: Minimizes waste by optimizing metal coil usage, ensuring each coil yields maximum output.

Conclusion

Hat purlins are a vital component in many construction projects due to their unique shape, variety in size and thickness, and multiple applications. The hat purlin roll forming machine enables efficient, high-quality production of these components, supporting construction demands in roofing, wall cladding, and structural frameworks. With their versatility, hat purlins continue to be an essential part of modern construction.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

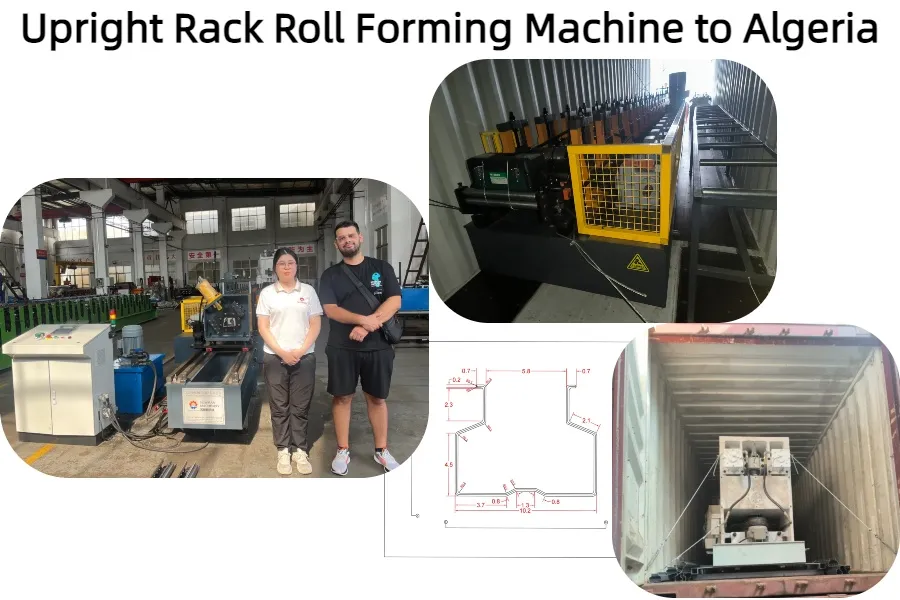

Upright Rack Roll Forming Machine Shipped to Algeria

.jpg)