-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Europea perforada galvanizada and pintro Tiras para cortinas roll forming machine

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Es un perfil fabricado con lamina de acero galvanizada y pintada; utilizada en la fabricación de cortinas metálicas enrollables. La tira de cortina plana tiene un diseño que le permite enrollarse de manera compacta cuando la cortina se abre y desenrollarse cuando se cierra.

The Tira para Cortina Europrea is popular in Latin America especically Mexico, it is widely used in roller shutter doors and windows.

Techncial Data:

|

Items

|

Specifications

|

|

|

Material of coil

|

Material Thickness

|

0.6 -1.0 mm galvanized

|

|

Un Coiler

|

3 tons manual

|

|

|

Forming system

|

Rolling Speed

|

About 0-10 m/min

|

|

Roller Stations

|

About 16 stations

|

|

|

Roller Material

|

Gcr15# Steel with quenching 60mm shaft

|

|

|

Maim Motor Power

|

7.5 kw

|

|

|

Hydraulic cutting Power

|

4 kw

|

|

|

Cutting

system |

Material Of Cutting

|

CR12Mov with quench treatment

|

|

Hardness

|

HRC58-62

|

|

|

Tolerance

|

+-1.5mm

|

|

|

Electrical control system

|

Electric Source

|

220V, 60HZ,3 phase

|

|

Control System

|

PLC with touch screen

|

|

|

Weight

|

About 3.5 tons

|

|

|

Way Of Drive

|

1 inch single chain

|

|

|

Size of machine

|

About Length 5800mm* Width 600mm* Height 1200mm

|

Machine List:

|

Name

|

Quantity (set)

|

|

3 Tons De-coiler

|

1 set

|

|

Main roll forming machine

|

1 set

|

|

Hydraulic Cutting

|

1 set

|

|

4 meters run out table

|

1 set

|

|

Control Box

|

1 set

|

|

Spare parts

|

1 package

|

|

Mesh Safety Cover

|

1 set

|

Working flow:

Decoiler— Feeding with guide—→Main roll forming machine——hydraulic cutting→ Run out table

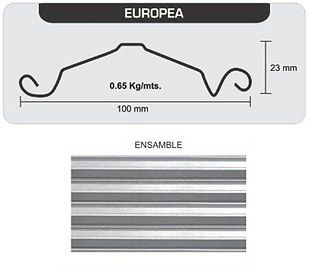

Profile Drawing:

Acabados: Zintro (verde)– Pintro (blanco, gris, ,azul).

Ancho: 98 mm.

Largo: Desde 1.00m hasta 8.00m.

Calibres: 24 – 22 – 20.

Surface: Plain, perforated, or micro-perforated

Also can do micro-perforations,allowing airflow and partial visibility while maintaining structural strength.

The holes made by press punching machine, it is can be separate line to do micro-perforations( which is decoiler---servo feeder----press punching---recoiler), then roll forming; or it is combined with roll forming machine(decoiler---servo feeder--press punching----roll forming---cutting---receiving table)

.webp)

.webp)

Main Tira Para Cortina Europea machine

.webp)

Two blades in one shear, it can be changed when one is broken and easily installation

Solid vs Micro-Punched Shutter Slats

| Feature | Solid Shutter Slats | Micro-Punched Shutter Slats |

|---|---|---|

| Design | Continuous metal surface, no holes | Small perforations (micro-holes) across the slat |

| Security | 🔒 Highest — no visibility through panel | 🔒 High, but slightly less secure than fully solid |

| Visibility | ❌ None — fully opaque | 🔎 Partial — allows view/visibility through |

| Ventilation | ❌ No airflow | 🌬 Allows air circulation |

| Lighting | ❌ Blocks light | ☀ Lets some light in |

| Aesthetics | Simple, clean look | Modern, technical appearance |

| Recommended Use | High-security areas (warehouses, industrial) | Commercial & retail storefronts |

| Wind Load Performance | Excellent (solid surface) | Good, but slightly less than solid |

| Privacy | Complete | Partial |

| Noise Reduction | Slightly better due to solid mass | Good, but micro-holes may leak some sound |

| Energy Efficiency | Better for fully enclosed thermal spaces | Better natural ventilation, less insulation |

| Cost | Often slightly lower | Slightly higher due to added perforation processing |

Applications

-

Commercial shops & storefronts

-

Shopping malls

-

Warehouses & factories

-

Garages and industrial buildings

-

Residential security shutters (windows & doors)