-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Round Square Downspout Tube Roll Forming Machine

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Main Features:

For the Downspout Tube Roll Forming Machine, there are two ways to make.

1, Roll Forming Machine first, then put the tube into the Elbow & Seaming Machine, 2 sets of machines.

2, United Downspout Tube Roll Forming Machine, roll forming, elbow & seaming together.

1.Technical parameter

Machine specification: Material: can be steel, colored steel or aluminum,

Material thickness: 0.3-0.6mm, yield strength 250 Mpa to 550 Mpa, coil width is according to the final profile, length is up to 12meters

Forming speed: 0-5m/min

Forming roller: about 24stations

Main motor power: 7.5KW

Hydraulic station power:5.5KW

Roller material: 45# forged steel, surface coated with chrome

Main shaft material: 45# steel

Main axis dia.: ¢68mm

Hydraulic cutting pressure: 10-12Mpa

Cutting method: hydraulic powered, cutting after roll forming.

Cutting blade material: Cr12Mov quenching treatment

Electrical controlling system: Whole line adopted PLC control, cut to length tolerance≤2mm

Drive method: Chain drive, made in China

Electric parts: Schneider brand

Touch screen: Delta

PLC: Delta

Encoder: Omron

Transducer:Yaskawa

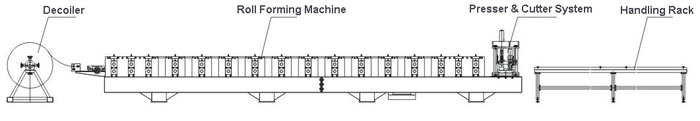

2.Machine List

|

Serial No. |

Commodity & Description |

Quantity |

|

1 |

3T manual uncoiler |

1 set |

|

2 |

Feeding with guide |

1 set |

|

3 |

Main roll forming machine |

1 set |

|

4 |

Straighten device |

1 set |

|

5 |

Hydraulic cutting device |

1 set |

|

6 |

Output table |

1 set |

|

7 |

Main drive |

1 set |

|

8 |

Hydraulic system |

1 set |

|

9 |

Controlling system (including cabinet) |

1 set |

|

10 |

Downpipe elbow device |

1 set |

|

11 |

Seaming device |

1 set |

|

12 |

Safety cover |

1 set |

|

13 |

Spare parts |

1 package |

3.Technical process

Uncoiling – Infeed Guiding– Roll forming – Straighten – Hydraulic cutting – Run-out table-elbow-seaming

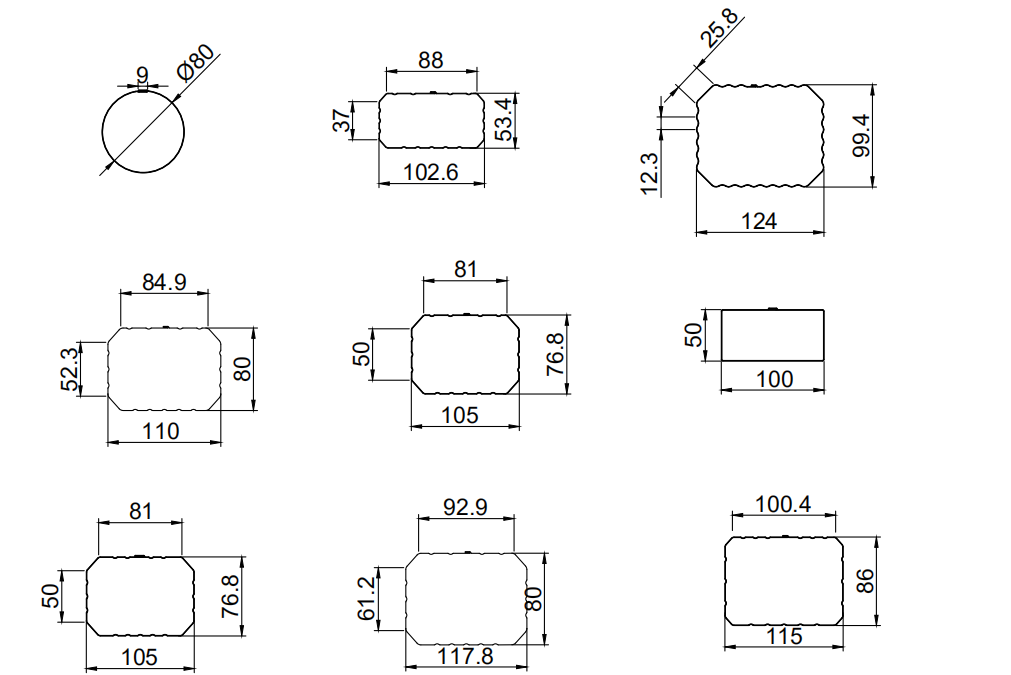

4. Profile design

5, Samples

6, Application

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

.jpg?x-oss-process=image/resize,w_100/quality,q_100)