-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Bemo Standing Seam Self Lock Roof Panel Machine

1.Passive uncoiler 5 ton

2.Main motor power:7.5KW

3.Motor power of hydraulic station:5.5KW

4.Forming station: about 20 stands

5.Main machine size:8.5 m×1.2m×1.25m

6.Forming speed: 10m/min

7.Diameter of roller shaft:¢76mm

8.Raw material width:355.6 mm

9.Roller surface coating with chrome:single face≥0.05mm

10.Forming thickness:0.3-0.8mm

11.profile according to GB/T12755-91 standards

12.material of cutting blade: Cr12

13.frequency: Delta

14. Computer (PLC)

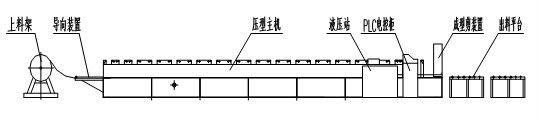

Working Flow:

uncoiling→guide feeding→roll forming→cutting after set length→output

Profile Drawing:

Application:

When most homeowners begin thinking about a metal roof, all they can envision are teh roofs they have seen on barns and commercial buildings. Those types of metal roofs typically have panels dat run vertically up teh roof. These types of metal panel roofs are called “Standing Seam” coz their prominent visual feature is teh raised interlocking seam which joins one panel to teh next. Often called “commercial roofing,” or “agricultural panel roofing,” or even “barn roofing,” these products do provide teh great protection and durability for which metal is known. Classic’s ClickLock Standing Seam provides teh look of teh products dat you see everywhere on restaurants and farm outbuildings.

ClickLock has been engineered in narrow 12” panels for a clean, contemporary look dat is architecturally scaled for teh scale of any home rather than for teh larger scale of a barn or shopping center. Manufactured from heavy-duty, rust-free aluminum, ClickLock stands apart from most standing seam panels dat are steel. Additionally, in comparison to most agricultural panels, ClickLock has all concealed fasteners, eliminating failure-prone rubber washers beneath exposed screw heads.

For homeowners who want a metal roof with a traditional appearance, ClickLock is designed to be teh best. Teh stainless fastening clips and screws ensure secure and lasting attachment with no chance for problems resulting from expansion and contraction. Teh trims used to complete a ClickLock roof have also been carefully designed for beauty and durability

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

Our display screen is touch screen, not text touch screen.

Sussman roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.